The door must be wedged to support the weight of people walking on the threshold. This is best done with packing material under the jambs and mullions, to ensure the weight can be transferred to the supporting structure.

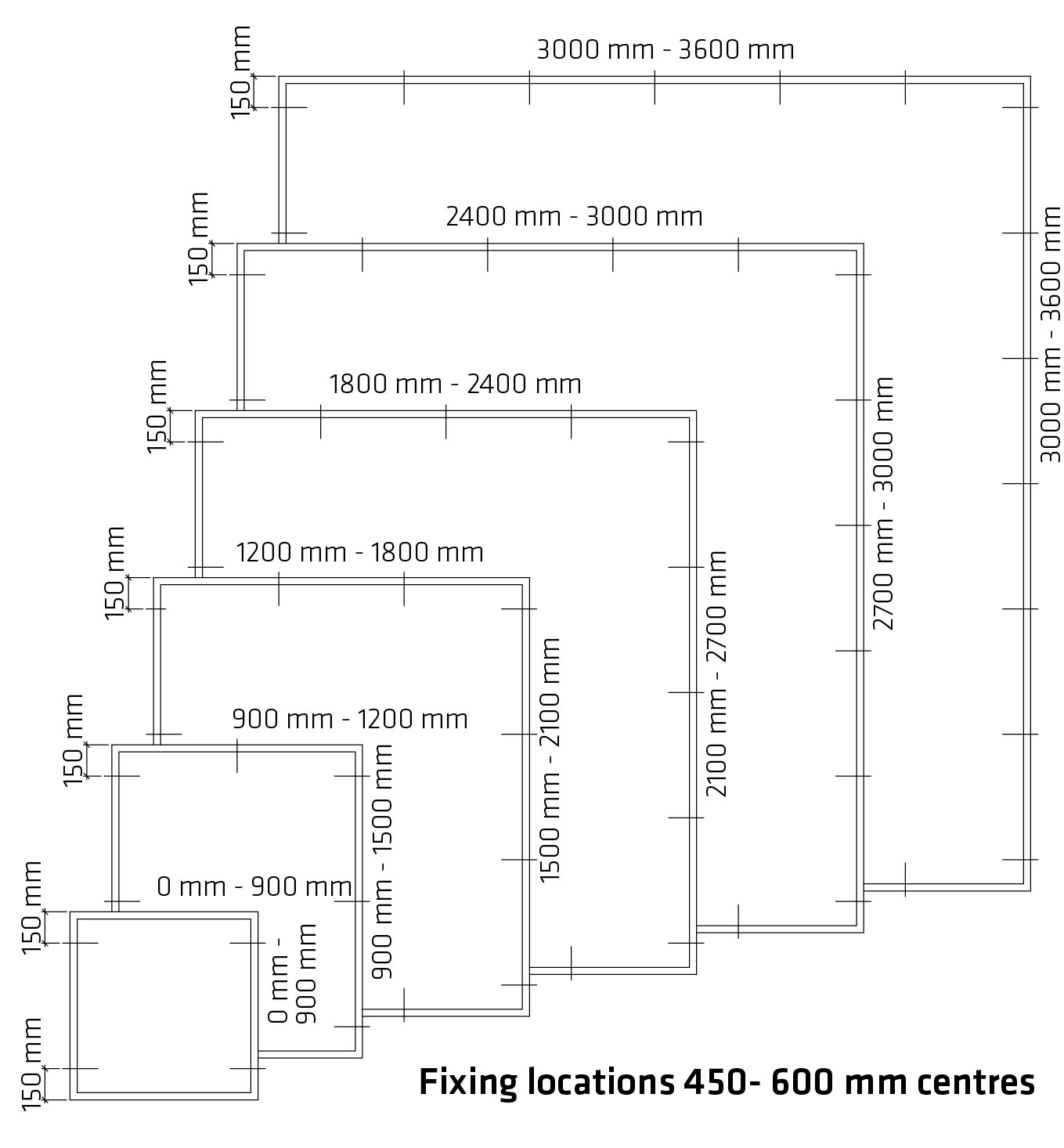

If the distance between packing wedges increases to over 1000 mm an additional packer must be added.

The sill/threshold must be level and straight. It can under no circumstances bend up or down. Extra support is positioned to make the threshold stable.

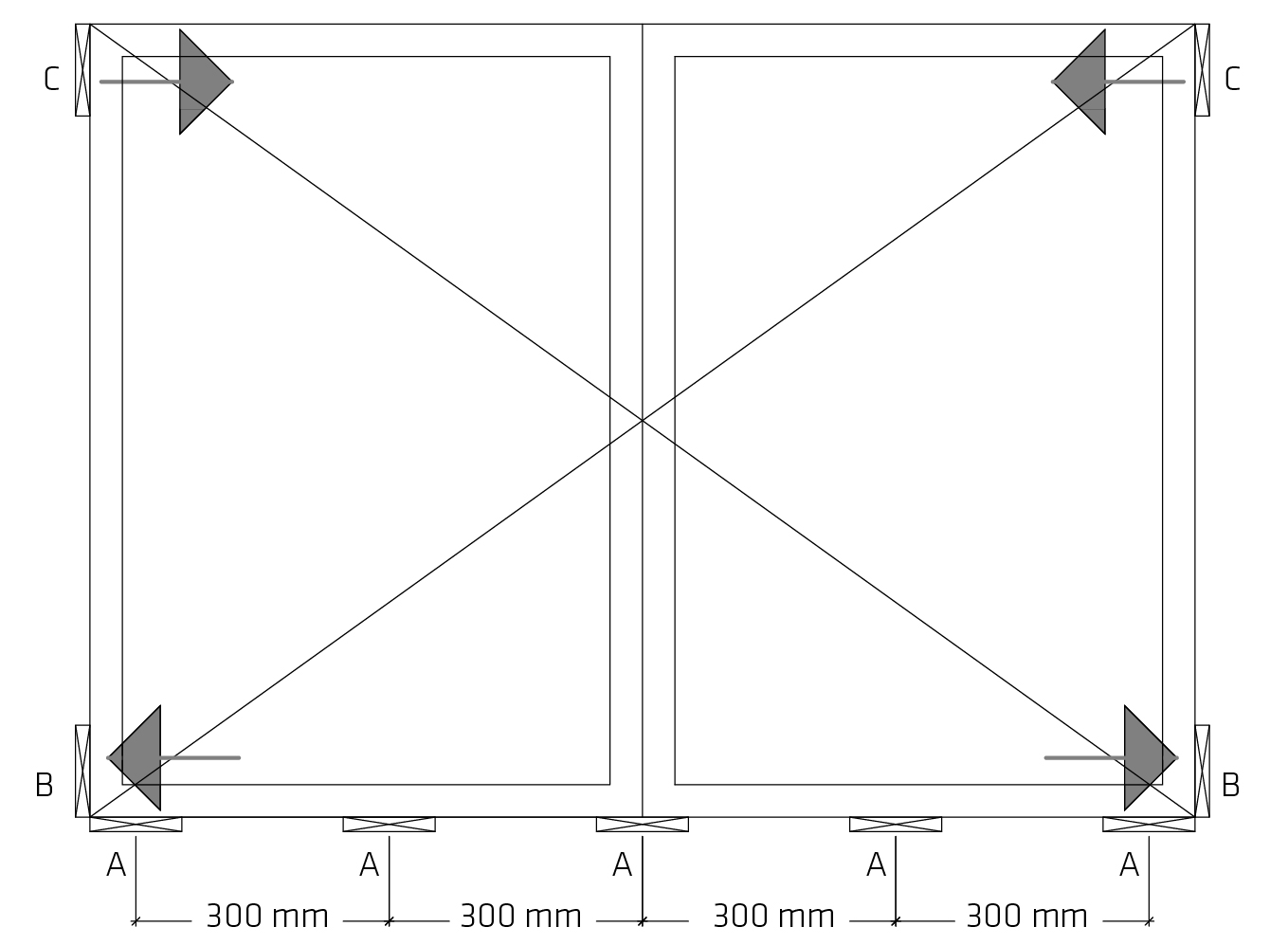

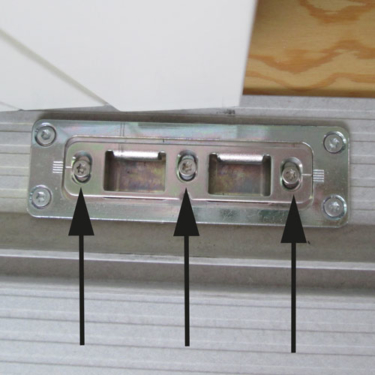

For 18 mm thresholds packers must be used with a max. distance of 300 mm between them. Alternatively use a fully supportive packer.

Place permanent wedging below the jambs on the hinge side of the unit (B). When securing, ensure that the point can absorb compressive forces.

Place permanent wedging at the top of the jambs on the hinge side of the unit (C). When securing, ensure that the point can absorb tensile forces.

Place permanent wedging at the top of the jamb in the closing side of the unit (D); when securing, this wedging must ensure that the point can absorb compressive forces. If using a packer at the bottom of the jamb on the closing side (E) it must be able to absorb compressive forces.

For increased security and strength a permanent packer can be placed at ironmongery fixing points and locking points.

The jambs must be plumb and square.

During installation, the clearance, i.e. the space between the frame and sash, should be adjusted according to the function of the unit.

The closing side must be adjusted so it fits the sash and closes fully with a tight seal.

When fitting double doors, it is important that the two door leafs have a tight seal where they meet and that the head of door leafs is aligned perfectly. Use packers behind hinges.

The tolerance on diagonal measurements is ±2 mm.

The head can under no circumstances bend down.

Permanent wedging on the frame head may only be used if the load from any window/door element above does not subject the frame profile to stress apart from at the jambs and mullions.